Training and Development Center

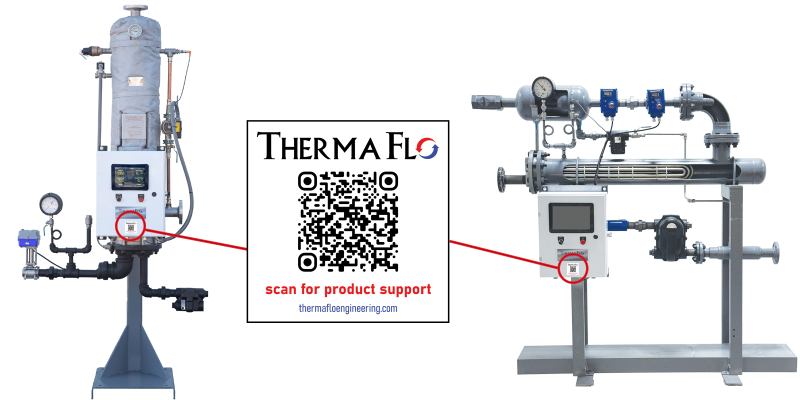

ThermaFlo’s Training & Development Center…Our 4,500 sq. ft. facility is fueled by our 6,000 lbs./hr. Steam System and features all of our water heating exchangers, clean steam generators, pressure operated pumps, EC1000 Bacnet controls, and steam-specialty equipment operating under load. Our goal is that this facility and the training will shorten the learning curve for our reps and demonstrate our products LIVE to engineers and customers.

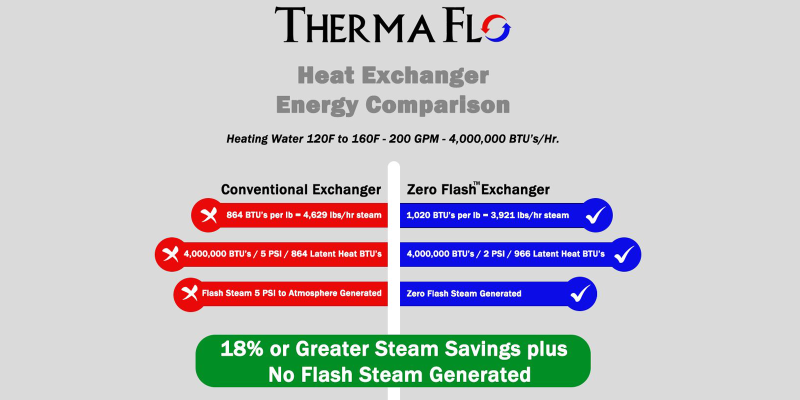

18% or Greater Steam Savings

H-500ZX Zero Flash Water Heater – 18% or Greater Savings Versus Standard Steam Heat Exchanger Systems!

Our Zero Flash System eliminates large steam pressure reducing valve stations and saves up to 40% over conventional heat exchanger installations. The JVV Segmented V steam control valve controls both temperature and steam pressure in the shell without pneumatics and has 300:1 flow turn down. The unique Zero Flash control system controls discharge temperature and steam in the shell to a low pressure simultaneously. All TH-500ZX units can be fitted with ASME safety valves.